Farm to fork, detecting the bacteria can be made easier, scientists say.

COLLEGE PARK, Md. — Worried about food safety? Is salmonella a big deal for you? Better, faster ways of spotting it may be on the way.

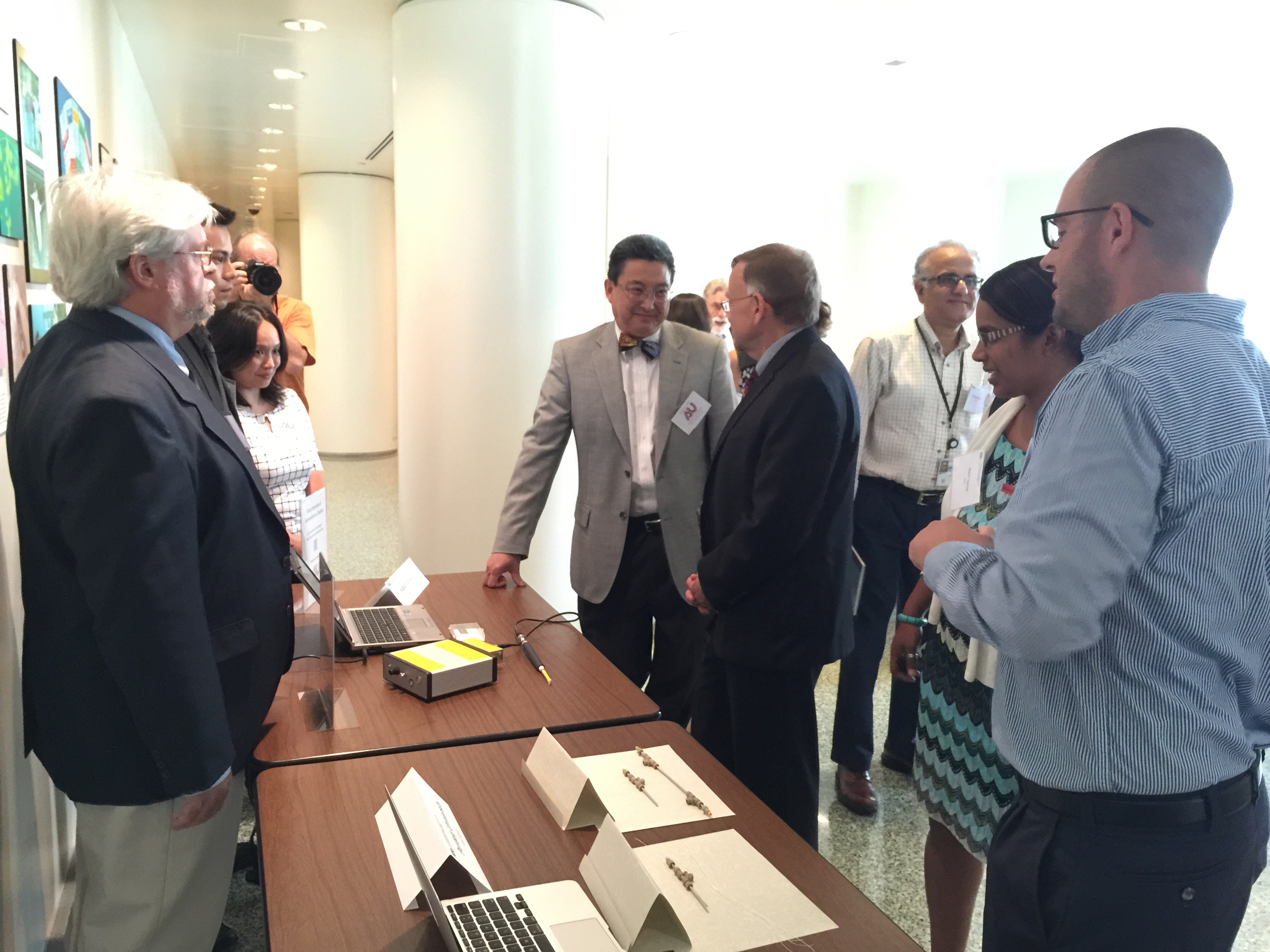

Researchers from universities and corporations presented their products at FDA’s 1st Food Safety Challenge this week, a competition where an innovative solution to food safety problems could be awarded up to $400,000.

A panel of judges from FDA and the Department of Agriculture saw a future of possibilities at a fair in suburban Maryland – an automated microfiltration system from Purdue University, pathogen-detecting biosensors from Auburn University, and flash readers from Pronucleotein Biotechnologies LLC in San Antonio, designed to identify bacteria in food within a couple of hours.

Achieving revolutionary improvements in the speed of FDA’s detection methods for salmonella in minimally processed fresh produce – tomatoes, for instance — was the main goal of FDA’s Food Safety Challenge.

Detecting salmonella – a type of food poisoning caused by bacteria in uncooked or undercooked food – is one tough challenge. Every year, it makes about one million people sick nationwide, afflicting unlucky eaters with diarrhea, fever and abdominal cramps.

However, manufacturers and analysts do not screen all food products, domestic or imported, because checking is time consuming and expensive, said John Bruno of Texas-based Pronucleotein Biotech, which was among five finalists.

Capt. Palmer Orlandi, acting chief science officer at FDA’s office of food and veterinary medicine, said the objective of the challenge is to find faster ways of finding and analyzing food samples that may be spoiled by harmful bacteria. FDA wants to “get answers quickly enough to address the problems,” Orlandi said.

In a conventional salmonella test, analysts spend hours preparing the food sample, concentrating it into high density to make it sensitive enough for bacteria to be detected. Five teams at the food challenge offered solutions to shorten this “enrichment” step. Two projects from University of California Davis and Auburn University in Alabama said that they succeeded in eliminating it.

Scholars from Auburn designed a magneto elastic biosensor, which makes on-surface detection of bacteria possible. Salmonella was discovered within 70 seconds during one experiment, said Bryan Chin, project leader at Auburn.

In the current environment, manufacturers must ship food samples to off-site test centers for bacteria detection – a system that increases costs.

During the competition at an FDA facility in College Park, five finalists offered solutions aimed at making salmonella detection not only easier, but portable. The idea is to give every key player in the food processing chain – from harvest and packaging, to distribution and retail – the ability to conduct food safety tests. The goal is to make “farm to fork” a risk-free journey for consumers.

The Food Safety Challenge was proposed in 2012 and started calling for submissions last September. The finalists, picked by a panel of food safety experts in May, received $20,000 to continue their work and also received mentorship from FDA experts.

The winner will be announced later this month, but the collaboration and interaction won’t end there.

“We have some fantastic ideas. That was the whole concept of our challenge,” Palmer Orlandi said. “There are so many needs for food safety. [This competition] is not a means to an end, but to building a relationship moving forward.”